In clay or poorly draining soils

Clay soils hold water longer, leading to prolonged saturation and higher hydrostatic pressure.

On the downhill side of sloped sites

Groundwater naturally moves downhill, causing increased water pressure against foundation walls on the low side of the building.

Where surface water is not directed away from the building

Improper grading, blocked downspouts, or short discharge lengths can allow water to pool near the foundation.

During heavy rainfall, snowmelt, or high water table conditions

Temporary rises in groundwater levels increase pressure against below-grade walls.

Why Waterproofing:

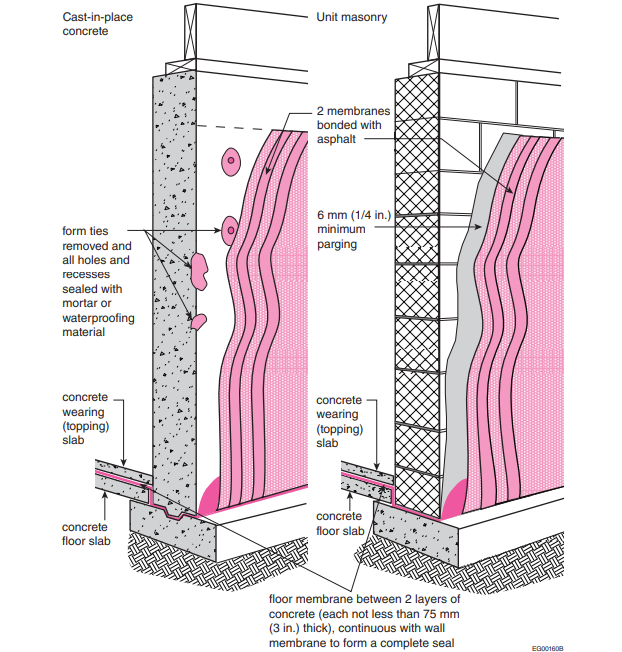

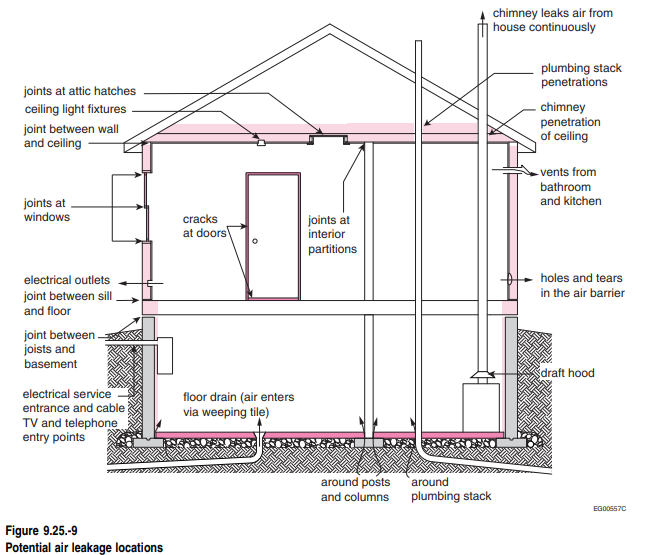

To prevent water infiltration

Stops water from seeping through cracks, pores in concrete, and construction joints, which will then prevent leaks and damp interiors.

To reduce structural damage over time

Repeated moisture exposure can cause cracking, spalling, corrosion of reinforcement, and long-term deterioration of foundation materials.

To protect interior spaces and finishes

Waterproofing helps prevent basement flooding, dampness, and damage to flooring, walls, insulation, and stored contents.

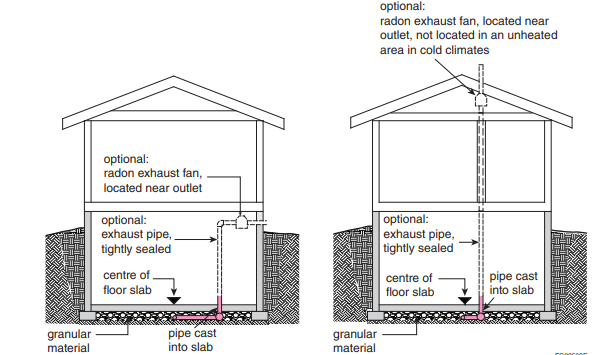

To limit mould and indoor air quality issues

Keeping moisture out reduces conditions that support mould growth and musty odours.

To improve durability and service life

Proper waterproofing extends the lifespan of foundations and reduces maintenance and repair costs.

To support effective drainage systems

Waterproofing works together with footing drains, drainage boards, and grading to manage groundwater and surface water.